All Regarding the Advantages of Buying a Top Quality Pallet wrapping Equipment

Purchasing a top quality pallet wrapping device can transform product packaging procedures. These machines give enhanced Load security, ensuring that items stay secure during transportation. They also decrease material waste by making use of stretch film effectively. Nevertheless, the benefits prolong beyond these factors. Discovering the complete variety of benefits reveals a much deeper influence on performance and safety within the office. Understanding these advantages can result in even more informed organization decisions. What other aspects should be considered?

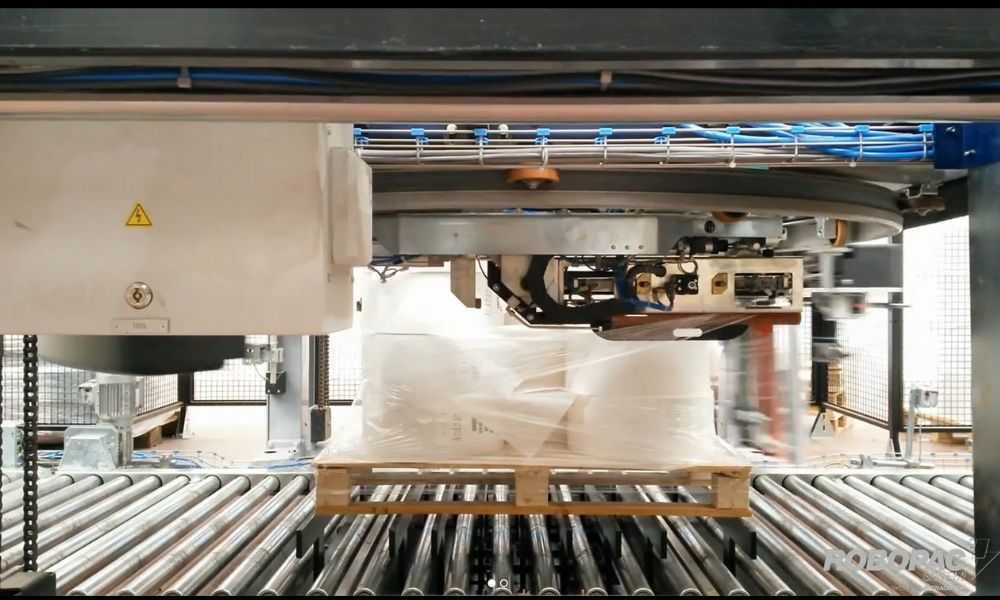

Boosted Load Stability

Boosted Load stability is an important advantage of purchasing a pallet wrapping machine. This machinery plays a necessary duty in safeguarding loads during storage and transport, minimizing the risk of moving or falling. By firmly wrapping pallets with stretch film, the tools assures that specific items continue to be in position, protecting them from damages. Boosted security likewise enables for much safer handling, lowering the probability of mishaps and injuries in the workplace. With improved Load security, business can take full advantage of area utilization in shipping containers and storage facilities, leading to extra effective operations. Ultimately, the enhanced dependability of palletized tons fosters self-confidence amongst clients, services, and distributors, boosting total supply chain performance and integrity.

Lowered Product Waste

Raised Efficiency and Speed

Purchasing a pallet wrapping device substantially increases effectiveness and rate in product packaging procedures. These equipments automate the wrapping process, permitting quicker preparation of goods for delivery. By lowering the time invested in hand-operated wrapping, organizations can improve throughput and reduce bottlenecks in the operations. Additionally, pallet wrapping equipments supply consistent results, guaranteeing that every Load is covered consistently, which eliminates the requirement for rework. This dependability not only quickens procedures but also contributes to far better stock monitoring, as items are planned for circulation extra promptly. On the whole, the integration of a pallet wrapping device causes a significant boost in performance, permitting business to satisfy consumer needs better and keep a competitive edge in the market.

Boosted Worker Safety

Decreased Handbook Handling Dangers

Carrying out a pallet wrapping device considerably lowers hands-on managing dangers, boosting total employee security in industrial settings. Typically, workers by hand wrapped pallets, revealing them to different physical strain and injury risks, consisting of training and twisting. By automating this process, the machine minimizes the requirement for employees to participate in repeated, laborious activities that can result in musculoskeletal conditions. Furthermore, the regular and safe and secure wrapping supplied by the machine lowers the likelihood of product falling or moving throughout transportation, reducing the threat of accidents. This not only secures the employees yet also guarantees the integrity of the items being taken care of. In general, purchasing a pallet wrapping maker cultivates a more secure office atmosphere by reducing hand-operated taking care of hazards efficiently.

Improved Ergonomic Style

The improved ergonomic style of pallet wrapping devices significantly contributes to improved employee safety and security and comfort. These equipments are engineered to minimize physical strain by permitting drivers to preserve a neutral body posture throughout operation. pallet wrapping machine repair. Attributes such as straightforward controls and adjustable heights make it possible for efficient handling without excessive flexing or getting to. In addition, numerous models consist of safety and security guards and automatic shut-off mechanisms to avoid accidents, even more protecting workers. By minimizing the physical needs of wrapping pallets, these equipments lower the danger of bone and joint injuries and fatigue, promoting a healthier job environment. Generally, purchasing an ergonomic pallet wrapping machine not just enhances efficiency however likewise demonstrates a dedication to staff member well-being and safety

Cost-Effective Product Packaging Service

While lots of services look for reliable methods to streamline their operations, a pallet wrapping maker sticks out as a cost-efficient packaging option. By automating the wrapping procedure, firms can greatly lower labor expenses and minimize the moment required for product packaging. This performance equates to higher productivity levels, enabling services to designate resources to various other vital locations. Additionally, a pallet wrapping equipment assists to reduce product waste, as it applies the correct amount of stretch film needed to secure items without extra. This not only brings about financial savings on packaging materials but additionally improves the honesty of the products throughout transport. In general, purchasing a pallet wrapping maker proves read what he said to be a smart economic decision for firms looking to maximize their packaging procedures.

Customization and Convenience

Customization and adaptability are key benefits of purchasing a pallet wrapping machine, enabling organizations to tailor their product packaging processes to certain item requirements. These makers frequently come with flexible settings to accommodate different sizes and shapes of pallets, making certain suitable wrapping for different tons. Users can choose the kind of wrapping material, thickness, and stress to improve performance and fulfill details operational requirements. In enhancement, progressed models provide programmable attributes, making it possible for fast changes between different packaging jobs without comprehensive downtime. This adaptability not only enhances the packaging procedure but additionally enhances efficiency by decreasing hand-operated changes. As an outcome, firms can successfully reply to changing demands while preserving a high requirement of presentation and functionality in their packaging solutions.

Much Better Item Security During Transport

Ensuring items arrive undamaged at their location is a vital concern for services, and buying a pallet wrapping device significantly boosts product protection throughout transportation. These makers use a safe and secure layer of stretch film around pallets, developing a steady system that lessens motion throughout delivery. This included stability aids protect against damages from shifting tons, environmental variables, and influences that can occur throughout the transportation procedure. Furthermore, quality pallet wrapping devices can provide wetness resistance, protecting items from wet problems. By properly sealing and protecting products, services can reduce the danger of loss and expensive returns due to damaged items. Inevitably, purchasing a pallet wrapping equipment proves important for keeping item stability and ensuring customer fulfillment.

Frequently Asked Questions

For how long Does It Take to Install a Pallet wrapping Machine?

The installment time for a pallet wrapping device typically ranges from a couple of hours to a number of days, depending upon the equipment's complexity and the facility's preparedness to suit the equipment.

What Upkeep Is Needed for a Pallet wrapping Machine?

Regular upkeep for a pallet wrapping maker consists of lubricating relocating parts, checking and changing used components, cleaning the device, and making sure correct calibration. Set up examinations assist prevent breakdowns and expand the Related Site devices's lifespan, boosting operational effectiveness.

Can a Pallet wrapping Machine Deal With Various Pallet Sizes?

A pallet wrapping equipment can usually handle various pallet sizes, depending upon its layout and requirements. pallet wrapping machine repair. Adjustable settings and functions permit operators to fit different measurements, making certain secure and efficient wrapping for varied tons

What Is the Average Lifespan of a Pallet wrapping Machine?

The ordinary life-span of a pallet wrapping maker normally varies from 5 to 15 years, depending upon the design, use regularity, maintenance techniques, and operational setting, affecting total efficiency and long-lasting financial investment dig this worth.

Exist Any Details Training Demands for Running These Machines?

The training needs for operating pallet wrapping makers typically include safety procedures, device operation methods, and upkeep procedures. Correct training warranties safe usage and makes the most of effectiveness, lowering the danger of accidents and devices damage in the work environment.

Additionally, pallet wrapping equipments offer regular outcomes, making sure that every Load is wrapped consistently, which eliminates the demand for rework. Spending in a pallet wrapping device substantially improves employee safety by minimizing the risks connected with hand-operated handling. Normal upkeep for a pallet wrapping device includes lubing moving components, checking and replacing worn components, cleaning up the maker, and guaranteeing correct calibration. A pallet wrapping device can usually deal with various pallet dimensions, depending on its style and specs. The training requirements for running pallet wrapping machines normally include safety and security procedures, device operation techniques, and upkeep treatments.